The Bylaw requires fermentation operations to:

- remove solids from wastewater and monitor

- install a sampling point

- control the pH of cleaning and sterilization wastewater

- record pH measurements, amount of packaged product produced and discharges of off-spec product

Remove solids

The discharge of coarse spent grains or fruit pulp to the sewer is prohibited.

The discharged wastewater must not exceed a Total Suspended Solids concentration of 1,200 mg/L.

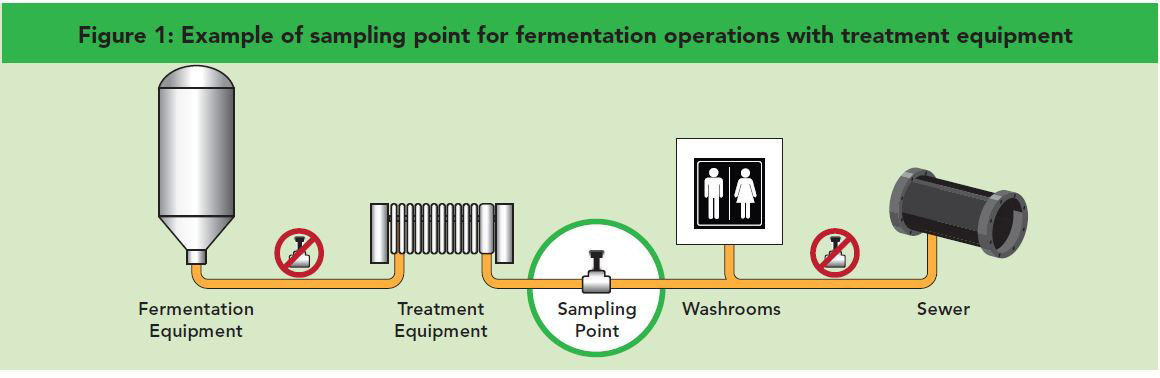

Install a sampling point

A suitable sampling point that can be accessed during operating hours must be installed.

A suitable sampling point must be:

- downstream from fermentation equipment and wastewater treatment equipment

- upstream from washrooms

- easily accessible

The sampling point will be different based on the scale and type of operation. Some examples of a sampling point are pictured below.

Example of sampling point for fermentation operations with treatment equipment

Examples of sampling points for fermentation operations without treatment equipment

Fermentation vessel

In some cases, samples can be drawn directly from a carboy or other small fermentation vessel.

Sink

In operations that rinse the fermentation vessel into a sink, it may be possible to simply plug the sink and take samples from there.

Sigot or check valve

Installing a spigot or check valve, either on a fermentation vessel or further downstream, may be considered an acceptable sampling point.

Trade waste interceptor

It may be possible to use an existing trade waste interceptor, as long as it is accessible and upstream of washrooms.

Sampling point must be located upstream of washrooms and other sources of wastewater unrelated to fermentation

Contact regulatory staff to discuss your options prior to installing a new sampling point.

Monitor and treat wastewater pH

On cleaning and sterilization days, operators must measure and record pH from the sampling point at least once during discharge to sewer.

The pH level must be measured immediately after sampling using a calibrated pH meter and be within the range of 5.5 – 10.5.

Keep records

All operators are required to keep the following records:

- Hectolitres (hl) of product packaged per calendar month

- Dates, time and results of pH testing

- Off-Spec product discharges of more than 100 litres per day

These records must be kept on site and available for inspection for a minimum of 2 years. For hectolitres of product, copies of data recorded for other regulatory authorities would be acceptable. Operators should use the

Fermentation Operations Bylaw Reporting Form for recording information about pH and off-spec discharge.

Manage discharge of off-spec product

Off-spec product (or 'bad batches') can be very high in Biochemical Oxygen Demand and is a burden on sewage infrastructure if discharged. Metro Vancouver must be notified prior to discharges of off-spec product greater than 100 litres. Operations inside the City of Vancouver must notify the City of Vancouver.

More detailed information can be found on the

Discharge of Off-Spec Product page.